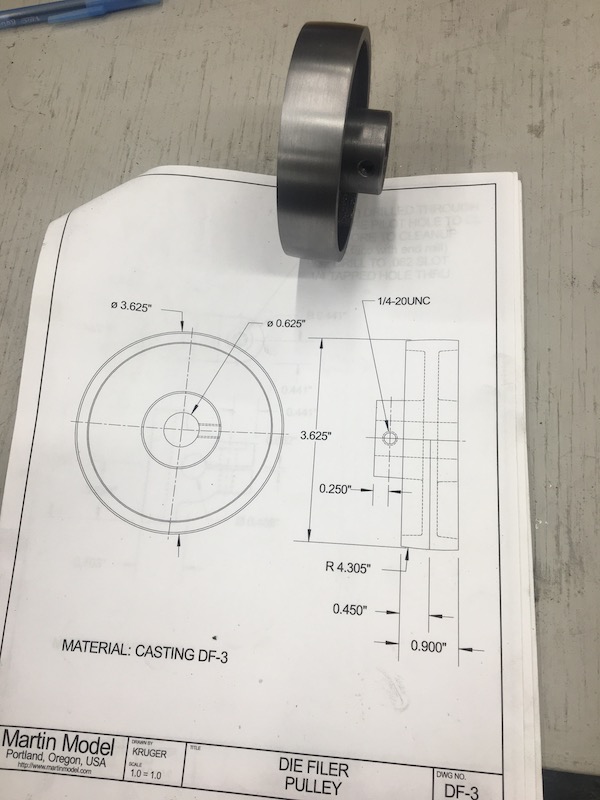

Making a drive pulley for the eventual motor. As usual, I know what motor I want to use, but shipping to Alaska is being a problem. *sigh* This is 6061t6 aluminum, ended up being 1.120" OD after I crowned it using another Youtube technique seen on the "That Lazy Machinist" channel. The print calls for a 4.305" radius on the crankshaft pulley, closest circular thing I had to that radius was an 8" steel target which I think is probably close enough to keep a flat belt in place. Basically you indicate off whatever you are using to establish the radius, and move the cross slide in to keep the indicator at zero as you traverse longitudinally. I did this in steps and then filed it until all the grooves went away.

Crowned pulley after polishing with scotchbrite and prior to parting off. I had gone in partway with the parting tool prior to crowning, to establish the edge on that side, so I just had to line it back up and finish the parting operation.

Completed pulley. Tomorrow I plan to crown the cast iron crank pulley.