Before I could start making connections in the electronics bay, I needed to flip the printer back on its feet and complete the above deck wiring. Most of this runs in drag chains down into the electronics bay. I found that with the Z belt tails on the right side secured how the build manual shows, that they interfered with travel of the drag chains, so I ended up cutting them both shorter, and securing the remaining tail to the belt with some kevlar thread from my fly tying supplies.

You can also see details in this picture such as the toolhead PCB, which provides a convenient location for connection of all the items on the print head, which are then run to a single connector for a separate wiring loom that runs through the drag chains and down to the electronics bay. There they connect to a breakout PCB, from which the individual circuits once again emerge to be connected to the BigTreeTech Octopus mainboard. The one-piece toolhead PCB was actually intended for the Afterburner/Clockwork 1 print head, while Stealthburner/Clockwork 2 use a different 2 piece toolhead PCB set. LDO came up with a set of modified parts to make this PCB work with SB/CW2, which is one of the things that necessitated re-printing some of the print head parts.

Rat's nest in progress.

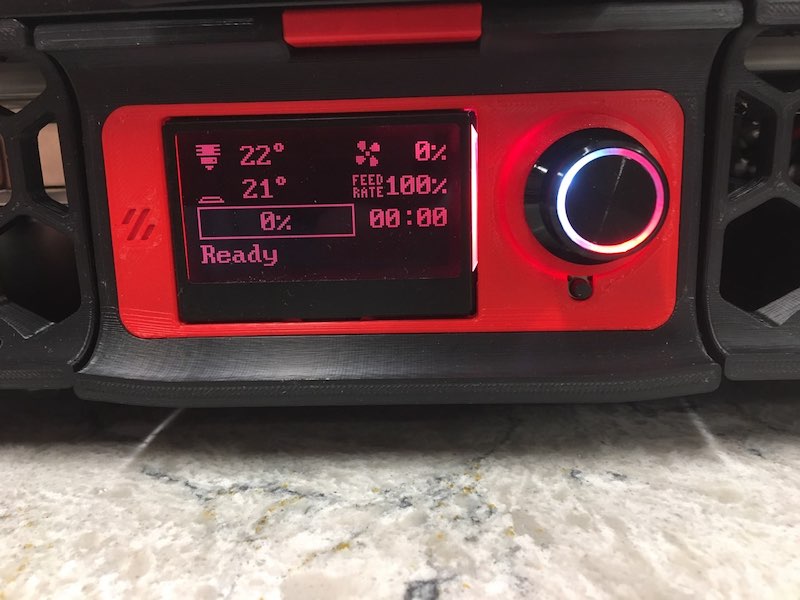

Wiring connections completed and secured. There is also a cover panel that goes over this; you can see the brass heat-set inserts for it on the skirts.

Panels and doors installed.